d·flux multi series

Multi-Parameter Mass Flow Meter & Mass Flow Controller for Gases

The d·flux multi series is a fast and reliable multi-parameter mass flow meter for gases with measurement outputs for mass, volumetric and normalized flow, pressure and temperature. One of the many advantages of this laminar flow meter is the ability to easily switch to a different gas without a loss in accuracy.

Meter and Controller

The unit is available as meter or with a strong integrated control valve as controller.

State-of-the-art communication

Advanced Modbus communication & analog output. Optional Profinet or EtherCAT interface available (Ethernet IP available soon)

Wireless device access with the free Vögtlin Connect app

Easy device access and configuration of many parameters with our free Android app (Bluetooth®).

Flow rates up to 1400 ln/min

Rate for air, other gases according to conversion (for instance hydrogen: up to 2900 ln/min).

Custom application profiles

The unit offers up to 15 application profiles, which allow the storage of individual application details like flow rate, gas, PID, etc. Every profile has an individual totalizer

Wide choice in materials

The units are available in aluminium (economical and light) and stainless-steel (all wetted parts). Elastomers are available in FKM, EPDM or FFKM. For hydrogen applications, we can supply a gold coated pressure sensor.

5 different sensor options

Our core sensor is an economical solution for air, nitrogen, oxygen and argon. Our prime sensor is suitable for all gases and has an high accuracy option. For hydrogen we recommend our gold-plated prime sensor./p>

Wide application scope IP54

Suitable up to 14 bar a and from -20 to 60 °C. Body in stainless-steel or aluminium Protection IP54.

Minimum inlet required

Compact design, requires no long straight or special inlet and outlet sections.

High accuracy, sample rate and fast response

Up to ± 0.3% user full scale and ± 0.5% of measured value.

High sample rate and fast response

Sample rate of 1 ms, updated data every 10 msec and a total response time of 120 msec (controller 2s).

Custom application profiles

The unit offers up to 15 application profiles, which allow the storage of individual application details like flow rate, gas, PID, etc. Every profile has an individual totalizer

Alarm, warning and diagnostic features

The d·flux multi series integrates advanced diagnostics, monitoring and reporting every part of its operation. The information is accessible via Vögtlin Connect app or Modbus

Autotare

To minimize uncertainty, the d·flux multi controller detects with an advanced algorithm when there is no flow and will then automatically zero (tare) for the unit optimum performance. For the meter this optimization needs to be performed manually.

Vögtlin Flow Studio Software

You can communicate to the d·flux in a Microsoft Windows environment through Modbus. To make this simple, we supply our free software. Easy to install, configure the unit and discover useful options such as graphs and data collection.

d·flux multi meter DFM

- Multi-parameter mass flow meter

- Flow rate up to 1400 ln/min for air

- Anodised aluminium or stainless steel 316L (1.4404)

- Modbus communication & analogue signals

- FKM, EPDM or FFKM elastomers

- Modbus and analogue output

d·flux multi controller DFC

- Multi-parameter mass flow meter

- Flow up to 1400 ln/min for air

- Anodized aluminium or stainless steel 316L (1.4404)

- FKM, EPDM or FFKM elastomers

- Modbus & analog output

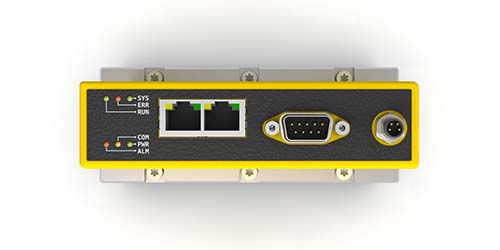

Analogue and digital interfaces

- The devices have Modbus and analogue output as standard.

- Interfaces for the Ethernet protocols PROFINET & EtherCAT are optionally available (EtherNet/IP™ coming soon).

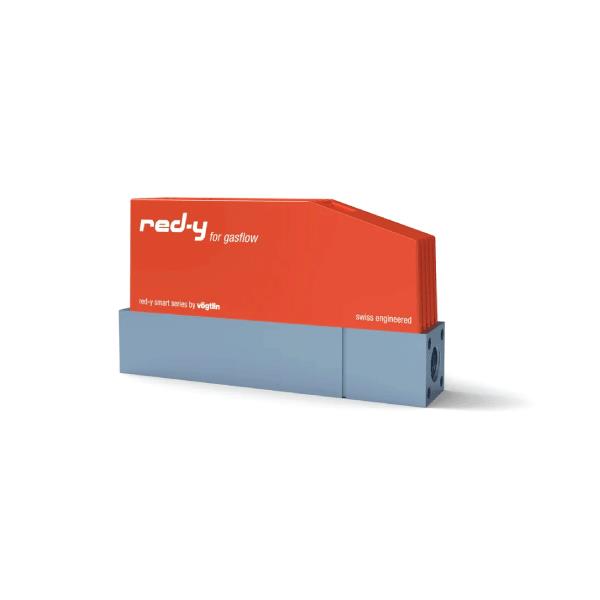

High-precision Thermal Mass Flow Meters & Mass Flow Controllers for Gases

Reliable technology and industry standard interfaces make the red-y smart series thermal mass flow meters (MFM) and mass flow controllers (MFC) particularly suitable for measurement and control in gas delivery systems and plant engineering applications.

Portable Battery Powered Digital Mass Flow Meters for Gases

The red-y compact series mass flow meters and regulators provide portability, flexibility, and convenience

The advanced compact unit can be equipped with various modules, including battery, power, alarm, or analog/pulse options. It is available in stainless steel or aluminum and features an intuitive backlit touch screen display, USB connectivity, and precise, reliable operation.

Rough Environment Mass Flow Meters & Mass Flow Controllers for Gases

Reliable technology and industry standard interfaces for rough environments: Our tried and tested thermal mass flow meters and controllers for gases of the red-y smart series now available as IP67 / NEMA 6 version.